However, this manufacturing method makes it difficult to create complex structures or intricate details.Īs a result, at Rockin H Farm Toys, we prefer the detail and durability of diecast models because they result in a higher-quality product that our customers can enjoy for generations to come. Metal toys and collectibles can also be made of stamped metal (a high-pressure press is used to bend and shape a flat piece of metal into the desired shape).

Why We Prefer Diecast Models To Other Manufacturing Methods After the metal cools, the die is removed and the item is sanded and finished as desired. Metal is melted and then forced, under pressure, into the steel mold. Now manufacturing of the diecast models can begin. The die is typically made of a high-grade steel that will stand up to high pressure and multiple uses. Once the prototype is complete, it is used to create the “die” (the form or mold that will shape our model).

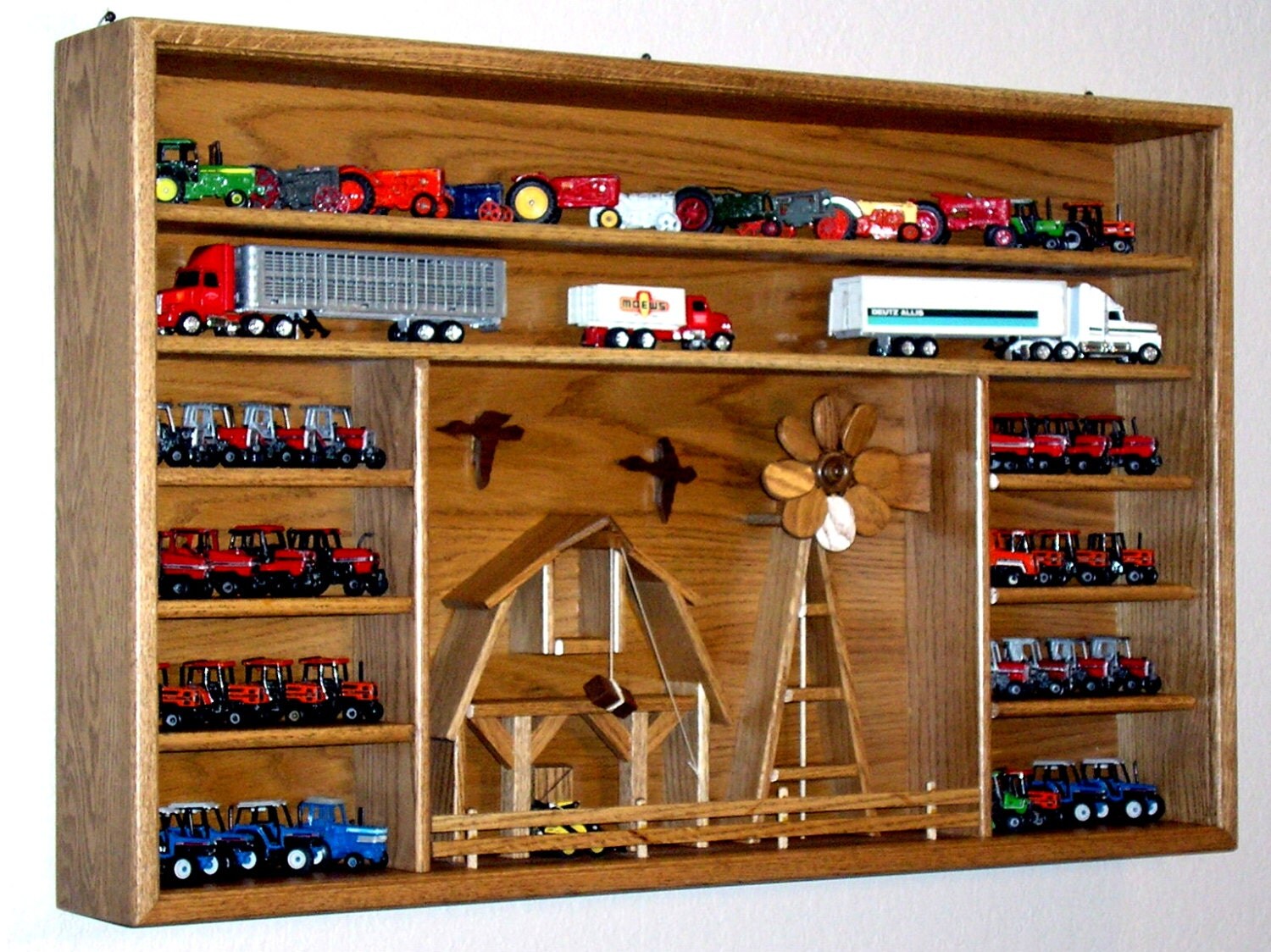

This can be painstakingly done by hand, or using newer 3-D modeling and Computer-Aided Design (CAD). The process of creating a diecast model begins with creating a prototype in clay. (Source: Wikipedia, November 2019) How Diecast Models Are Madeīefore explaining how diecast models are made, you should understand what the term “diecast” (or, more accurately, “die-cast”) means.ĭie-cast is a manufacturing process that uses a lot of pressure to force molten metal into a “die” (a form or mold) that is used to make the metal take a desired shape. From 1977 to today, diecast models are most commonly made of a zinc alloy known as Zamak. Popular diecast models you may have owned or played with as a child include Matchbox™ and Hot Wheels™.īefore 1977, diecast models were made of a lead alloy. Diecast models are metal replicas of real-life items like semi trucks, farm machinery, agricultural equipment, and more.

0 kommentar(er)

0 kommentar(er)